Robot welding advantages over manual welding

Robotic welding

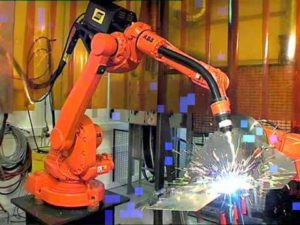

The robot welding is the use of the mechanized programmable tools ( the robots ) , The robots completely automate the welding process through performing the weld and handling the part , They are commonly used for the resistance spot welding and the gas metal arc welding in the high production applications like automotive industry .

Welding is the process where two materials are fused together through heating , intermixing then cooling the materials and filler to form the strong join , The robotic welding is the automated process which increases efficiency , consistency and your ROI .

All of the welding parameters are controlled in the automatic welding , The manual adjustments may be made between welding operations but not during welding , while in the robotic welding , The automatic welding is using the robot which can be pr-programmed to different welding paths and fabrication geometries .

Advantages of robot welding over manual welding

Automating the factory with welding robotics offers consistent cycle times , no break in the production and better weld quality , Welding robotics are faster , The robotic weld cells work productively because they can work without breaks or days off .

The robot welder is more consistent and it can move from one weld to the next quickly , speeding up the entire process , by using welding robotic automation , the process takes less time and the manufacturers can cut the cost of direct labor , safety and conserve materials .

The robot welder takes less time , The robotic welding systems will get the job done quickly , They have fewer mistakes than manual welding , Unlike the laborers , The robots don’t require the breaks , The vacations , etc , The work can continue without interruption , 24/7 , The robots will increase your throughput & productivity .

The robot welder cuts the cost of direct labor & safety , The manual welding cost can be steep , The manual welding requires the time , the skill and the concentration and it is also dangerous , Welding is the very dangerous application , The flash , the fumes , the sparks and the heat make the manual welding a taxing and hazardous job .

With the robotic welding , you will protect the workers and reduce the costs , These systems endure the hazards and increase the production , The insurance and accident related costs are reduced considerably .

The robots conserve the materials , Even the most skilled welders make the mistakes , with new and used welding robotics , everything is regulated , including the power and the wire , The robotic welding becomes increasingly attractive for the job shops and contract the manufacturers

The welding robotic systems conserve the energy , The accuracy of the robot systems reduce the wasted material and the time , The robots welding conserve your material and increase your product quality at the same time .

The robotic welding allows you to use the labor pool with low price , The manual welding personnel are very expensive and they are difficult to find , train & retain , With the robotic welder you can optimize your staff by having only a great welder supervising the work of many automated cells instead of having to find and train a lot of welders for the job .

The automation can place the same quality welds in the same spots routinely , with minimal human error , They eliminate the repetitive boring jobs which could be the factor in welder turnover , The robots reduce the total time , They increase the production , They provide large gains in the productivity & the profitability in the right applications .

The robots cause less post-weld cleanup, The robotic welding are very precise, They allow for less weld spattering and neater seams, They reduce the cost of consumable materials, The filler material and weld wire are used with the robotic welding more economically and less wastefully , So , They reduce the overall cost of the product .

Automation in manufacturing uses , advantages and disadvantages

Industrial robot ( Auto industry ) uses , advantages and disadvantages