3D Printing (Additive and Subtractive Manufacturing) uses, types, cons and pros

3D printable models can be created with the computer-aided design (CAD) package via the 3D scanner or by a plain digital camera and photogrammetry software. 3D printed models created with CAD result in reduced errors that can be corrected before printing, allowing verification in the design of the object before it is printed.

3D Printing

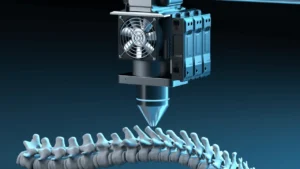

3D printing is also known as additive manufacturing (AM). It refers to the processes used to create three-dimensional objects, in which layers of material are formed under computer control to produce the objects. So, there is no waste.

The objects can be of any shape or geometry and are produced using digital model data from the 3D model or another electronic data source, such as the Additive Manufacturing File (AMF).

3D printing is the process that deposits the binder material onto the powder bed with inkjet printer heads layer by layer. It is used in many additive manufacturing techniques such as binder jetting, directed energy deposition, material extrusion, material jetting, powder bed fusion, sheet lamination & vat photopolymerization.

Before printing the 3D model from the STL file, it must first be examined for errors. Most CAD applications produce errors in output STL files, holes, face normals, self-intersections, noise shells, or manifold errors. The step in the STL generation known as repair fixes such problems in the original model.

3D Printing advantages

3D Printing offers design freedom, incorporates intricate features, It can reduce labor, It presents high speed, The customers’ high interest among customers in 3D printing. It offers high-quality prototyping without having to learn or buy into the range of increasingly rare and expensive conventional modelling skills.

3D printing is employed to produce the workable parts for many industries, including the medical, dental, aerospace, and automotive sectors. It speeds up the product development phase of the projects. It can produce professional mock-ups for exhibitions & trade shows in conjunction with traditional model making.

The traditional manufacturing requires expensive tools, and it can be a very wasteful process, as often much of the original raw material is thrown away during the manufacture of the product.

3D printing produces the customised goods quickly & relatively cheaply. It is used to produce multiple products which are identical apart from their customised components without adding the processing costs associated with more traditional techniques.

As the product is created directly from the printer, both the labor time & costs can be reduced, where the products have to be delivered to tight time schedules and budgets. There is very little waste. Minimum waste makes this a low-cost, sustainable production method.

3D printing uses less material. It creates minimal waste, mitigating the need for expensive recycling processes. The components can be made both lighter and stronger, so they are more eco-friendly because their impact is less.

The complex components are produced to be stronger and lighter, such as in the aerospace sector. The planes made with lighter components will weigh less overall. They consume a smaller amount of fuel and do not produce as much C02 emissions.

3D Printing can quickly produce the components. 3D printing during product development is referred to as rapid prototyping. For final production parts, it can be described as rapid manufacturing.

3D printing is useful for small production batches or limited mass production, and for creating the required moulds for this type of manufacturing. It enables decentralisation, saving transport costs and driving down overall logistics expenses.

Additive Manufacturing

Additive manufacturing is the process of creating the product by using various methods to bind layers of material together, while subtractive manufacturing is the well-established method to produce consistent products by removing the excess material.

Additive Manufacturing is quicker compared to other conventional methods of prototyping and manufacturing. Depending on the complexity and size of the component, many parts can go from CAD model to finished parts in minutes or hours.

Very complicated geometry and shapes can be printed that couldn’t be produced by conventional manufacturing processes. Design engineers are free to design for the optimum ideal form. Plastic and metallic parts can be produced in this way.

You can print the parts in different colours with some 3D Printers. The selected 3D printers can print two different materials. The 3D printed parts can be surface finished and painted as well as drilled, tapped, and sanded down – all ideal for presentation purposes.

There are infinite shades of materials. The engineers can program the parts to have specific colours in their CAD files, and the printers can use the materials of any colour to print them.

The additive manufacturing describes the technologies that build 3D objects by adding layer-upon-layer of the material, whether the material is plastic, metal, concrete, or one day… human tissue.

AM encompasses many technologies contains subsets such as 3D Printing, Rapid Prototyping (RP), Direct Digital Manufacturing (DDM), layered manufacturing, and additive fabrication. AM application is used to fabricate end-use products in the aircraft, Dental restorations, Medical implants, Automobiles and Fashion products.

The complex products are produced quickly & with minimal lead times, So, the additive manufacturing is the ideal method for developing the prototypes or low volume/custom products. 3D printing uses nearly 100% of the raw material, leading to minimal, if not zero, waste.

Subtractive Manufacturing

We can carve the figure from the block of wood. We start with our material, then using the assortment of tools, we whittle down the material, layer by layer, until we end up with our finished model. We subtract the material we don’t want from the material until we’re left with our product.

Subtractive manufacturing can be used to make products out of wood, metals, stone, and ceramics. On a larger scale, the subtractive manufacturing may also be less expensive than additive manufacturing.

3D Printing Disadvantages

3D Printing has high equipment cost, It has high material cost, It has a risk of pattern distortion during printing, It is difficult to repair or modify the pattern made through 3D printing, and the potential distortion of 3D printed patterns by hot foundry sand.

The final parts may have internal voids. The additive manufacturing is still remains best suited for the smaller batches of product, but when it comes to scale, the subtractive manufacturing is both more efficient and less expensive.

Although subtractive manufacturing may be less expensive, it is also less efficient when producing complex parts, and it lacks the key ability to create hollow sections within the product.

Subtractive manufacturing requires a great deal of setup and programming precision, leading to longer lead times than 3D printing, and the subtractive manufacturing results in more wasted material.

The technology is still very much in its infancy; it may well address limitations such as the type of material that can be produced in the 3D environment. The print speed can be improved over time, but the other computer-based manufacturing techniques may sometimes be preferable if time is a vital factor.

3D printing techniques are not always easy to master, and in-depth training is often required to manage these complex machines. This can, of course, be costly to the manufacturers, and these costs may end up being absorbed by the consumer.

You can follow Science online on YouTube from this link: Science online