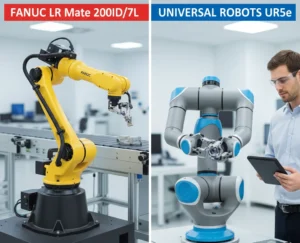

LR Mate vs UR5: Comparison between the FANUC LR Mate series and the Universal Robots UR5

Industrial and collaborative robots have become essential tools across modern manufacturing, research, and production environments. Among the most popular robotic systems in these categories are the FANUC LR Mate series and the Universal Robots UR5, each representing a different philosophy in automation design.

LR Mate vs UR5

A comprehensive comparison between the FANUC LR Mate series (classic industrial robot arms) and the Universal Robots UR5 (a collaborative robot):

The FANUC LR Mate is a compact, high-precision industrial robot arm engineered for speed, repeatability, and continuous 24/7 operation in automated production lines. It is widely used in applications such as assembly, material handling, machine tending, and vision-guided tasks where strict cycle times and industrial robustness are required.

On the other hand, the Universal Robots UR5 is a versatile collaborative robot (cobot) designed to work safely alongside human operators without the need for heavy safety barriers. With intuitive programming and rapid redeployment capabilities, the UR5 is favored for flexible automation scenarios such as light assembly, inspection, packaging, and laboratory handling, especially in environments that demand human-robot interaction and adaptable workflows.

FANUC LR Mate (Industrial Robot)

The LR Mate series are compact, high-speed industrial robot arm made by FANUC. They’re designed for traditional automation tasks in factories and production lines. These are non-collaborative, meaning they typically require safety guarding and integration into automated cells.

- Axes: 5–6 (depending on model).

- Payload: ~4–14 kg.

- Reach: ~550–911 mm (depending on variant).

- Typical industrial controller: FANUC R-30iB series.

- Mounting: Floor/ceiling / angle / inverted.

- Repeatability: ~0.01 mm.

- Often used with vision, force sensors, and offline programming tools.

Universal Robots UR5 (Collaborative Robot / Cobot)

The UR5 is a collaborative robot (cobot) from Universal Robots designed to work safely alongside humans in shared spaces without heavy safety cages. It’s easier to program and integrate into versatile workflows, and it is ideal for companies that want flexible automation with minimal setup.

- Axes: 6.

- Payload: ~5 kg.

- Reach: ~850 mm.

- Designed for: Collaborative use and flexibility.

- Programming: Intuitive graphical interface + scripting (URScript).

LR Mate (FANUC Industrial) Features

- High performance & rigidity: Industrial-grade actuators and structure designed for continuous operation and high repeatability (~±0.01 mm).

- Flexible physical mounting: Mount on floor, ceiling, wall, or inverted angles for compact cell design.

- Fast motion & throughput: Powerful servos with short cycle times and high acceleration.

- Wide model variety: Short/long reach arms, different payloads, cleanroom and washdown variants available.

- Integration with industrial software: LR Mate supports offline programming (like ROBOGUIDE), vision systems, force sensors, and third-party automation tools.

UR5 (Universal Robots) Features

- Collaborative operation: UR5 is designed to work alongside humans without a safety cage (force/torque sensing, power/force limiting).

- Ease of programming: User-friendly graphical interface, drag-and-drop task setup, quick redeployment for new tasks.

- Flexible deployment: Easily reprogrammed for different tasks, making it great for SMEs or changing production workflows.

- Lightweight and compact: ~18 kg body weight makes it easy to reposition or set up on different cells.

FANUC LR Mate advantages

- Industrial reliability & durability: FANUC LR Mate is built for long-term 24/7 operation.

- High speed & precision: FANUC LR Mate is excellent for classic pick-and-place, assembly, and handling tasks.

- Strong ecosystem: Mature tooling, programming languages, and integration support.

- Versatile mounts & heavy payload options: FANUC LR Mate can be adapted to many automation scenarios.

FANUC LR Mate disadvantages

- Requires safety guarding: FANUC LR Mate cannot be used directly in shared workspaces with humans due to safety.

- Steeper learning curve: Advanced programming may require skilled technicians.

- Higher integration cost: FANUC LR Mate requires project integration, cabling, controllers, safety features, etc.

UR5 (Universal Robots) advantages

- Collaborative & safe: UR5 works near humans without heavy guarding.

- Easy to program & redeploy: Short learning curve with intuitive graphical programming.

- Highly flexible: UR5 is good for varied tasks across departments.

- Lower initial setup cost: Less complex than traditional industrial robot cells.

UR5 disadvantages

- Slower speed limits: Collaborative safety standards limit aggressive motion speeds versus traditional robots.

- Lower payload & reach — Payload ~5 kg vs LR Mate up to ~14 kg.

- Not ideal for heavy industrial duty: Better suited to light to medium automation.

Comparison between the FANUC LR Mate series (classic industrial robot arms) and the Universal Robots UR5 (a collaborative robot)

What They Can Do — LR Mate vs UR5

The FANUC LR Mate is built for classic industrial automation tasks where speed, precision, and durability are required. It excels in assembly operations, high-speed pick-and-place, machine tending for CNC machines, sorting, packaging, and material handling within fully automated production lines. When paired with industrial vision systems, the LR Mate can perform complex part recognition and orientation tasks, making it suitable for high-volume manufacturing environments that demand continuous 24/7 operation and strict cycle-time performance.

In contrast, the Universal Robots UR5 is a collaborative robot (cobot) designed to safely work alongside human operators without requiring large physical safety barriers. It is commonly deployed for light assembly, quality inspection, bin picking, packaging, test automation, and laboratory handling tasks where workflow flexibility matters. One of the major strengths of the UR5 is its ability to be quickly reprogrammed and redeployed for new applications, making it ideal for small-batch or mixed-production facilities as well as research and educational environments.

From a human-interaction standpoint, the LR Mate is typically restricted to enclosed robotic cells due to its high speeds and industrial nature, while the UR5 features force-sensing and power-limiting safety functions that allow it to operate in shared workspaces. However, this collaborative design also means that the UR5 is generally slower and lower in payload capacity compared to the LR Mate. Therefore, the LR Mate is preferred in applications driven by cycle time and throughput, while the UR5 is favored for applications driven by flexibility, ease of integration, and human-robot collaboration.

Applications of LR Mate

- Assembly automation.

- Machine tending.

- Pick-and-place in high-throughput lines.

- Integration with vision systems for precision tasks.

Applications of UR5

- Collaborative loading/unloading.

- Quality inspection with vision addons.

- Light assembly and packaging.

- R&D labs and flexible production lines.

LR Mate is a traditional industrial robot — robust, fast, precise, and ideal for classic manufacturing automation where safety cages and skilled integration are acceptable. UR5 is a collaborative robot — simpler to use, safe for human interaction, and flexible for dynamic environments, but with compromises in speed and heavy payload capacity.

You can subscribe to Science Online on YouTube from this link: Science Online

FANUC LR Mate Robot: Definition, Features, Advantages, Disadvantages & Applications

Collaborative robot applications, Universal Robots, UR3, UR5, UR10, e-Series uses and importance

Scara robot advantages and disadvantages and What is the structure of the SCARA robot?

Serial Robots review, advantages, disadvantages and what can serial robots do?

Collaborative robot arm (cobot robots) applications, uses, advantages and disadvantages

Automation in manufacturing uses, advantages and disadvantages

Industrial robot (Auto industry) uses, advantages and disadvantages

Robot welding advantages over manual welding