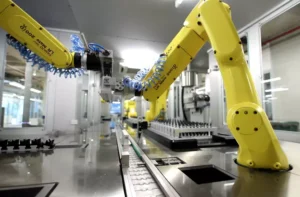

FANUC LR Mate Robot: Definition, Features, Advantages, Disadvantages & Applications

The LR Mate is a compact 6-axis industrial robot produced by FANUC, designed to perform precise automated tasks in small spaces such as production lines, laboratories, workshops, packaging stations, and cleanrooms. It is widely referred to as a tabletop-sized robot because its working footprint is small, while still offering high speed and reliability.

What is the LR Mate robot?

The LR Mate is a compact 6-axis industrial robot from FANUC designed for automated handling, assembly, packaging, inspection, and machine tending tasks in small production environments and laboratories.

What is FANUC LR Mate used for?

The LR Mate is used for pick & place operations, product assembly, packaging, loading machines, quality inspection using vision systems, lab automation, food handling, and material removal processes like grinding or polishing.

What are the advantages of LR Mate robots?

Key advantages include compact size, high precision, low energy consumption, multiple variants, compatibility with vision systems, flexible mounting options, low maintenance requirements, and proven FANUC reliability.

Is LR Mate a collaborative robot?

The LR Mate itself is not strictly classified as a collaborative robot, but it can operate near humans when integrated with safety options such as sensors, fencing, or force-limiting systems. True collaborative alternatives exist in other robot families.

What industries use the LR Mate robot?

The LR Mate is widely used in automotive, electronics manufacturing, pharmaceuticals, medical device production, food processing, research labs, packaging platforms, and aerospace component assembly.

How much payload can the LR Mate handle?

Depending on the model, the LR Mate typically handles payloads between 4 kg and 14 kg, making it suitable for lightweight tools, components, and inspection devices.

What are the different types of LR Mate robots?

The LR Mate family includes several specialized variants, such as:

- standard industrial models.

- long-arm versions.

- high-payload versions.

- cleanroom models.

- food-grade & washdown versions.

- vision-ready models.

Each is optimized for specific industrial requirements.

Is LR Mate suitable for cleanroom environments?

Yes. FANUC offers cleanroom-rated LR Mate models designed for contamination-controlled environments such as semiconductor labs, pharmaceutical facilities, and medical device manufacturing.

How accurate is the LR Mate robot?

The LR Mate offers high repeatability, often around ±0.01 mm to ±0.03 mm depending on the configuration, making it suitable for precision assembly and inspection tasks.

What is the price of a FANUC LR Mate?

The price varies based on the model, payload, peripherals, and vision systems. Typical industrial configurations range approximately from $25,000 to $45,000 USD, and can exceed that when adding tooling, safety systems, or integration services.

Does LR Mate support vision systems?

Yes. The LR Mate is compatible with 2D and 3D vision systems, including FANUC iRVision for detection, orientation, inspection, quality control, and robotic guidance functions.

Is LR Mate good for machine tending?

Yes. The LR Mate is commonly used for CNC machine tending, injection molding automation, and small-part loading/unloading due to its compact size, precision, and endurance in continuous operation environments.

The LR Mate family is known for:

- compact design.

- high repeatability.

- multi-tool compatibility.

- flexible mounting options.

- industrial-grade durability.

Features of LR Mate Robots

The LR Mate series includes multiple generations, but they typically share the following features:

- Six Degrees of Freedom: The LR Mate series allows flexible movement similar to a human arm, enabling handling, assembly, machining, pick & place.

- Small Footprint: The LR Mate series is designed for small production cells or desktop applications without requiring major space modifications.

- High Payload Capacity: Depending on the model, payload ranges from 4 kg to 14 kg, enabling precise manipulation of tools and parts.

- Vision System Compatibility: LR Mate series supports 2D & 3D vision, including FANUC iRVision for quality inspection, object detection, orientation, and measurement.

- Cleanroom & Washdown Models: Specialized versions exist for: food handling, pharmaceutical labs. medical device assembly, and electronics manufacturing.

- Multiple Programming Options: LR Mate series Supports teach pendant, Offline programming, ROS integration, and Industrial automation software.

- Energy Efficiency: Low power consumption compared to larger industrial robots.

Types & Variants of LR Mate Robots

The LR Mate family includes different specialized variants, for example:

- Standard Models: General-purpose for handling, assembly, and automation tasks.

- Cleanroom Models: Designed for contamination-controlled industries like semiconductors, pharmaceuticals, and medical labs.

- Food-Grade / Washdown Models: Use corrosion-resistant materials for packaging, food handling, and FMCG production.

- Long-Arm Models: Increased reach for wider work envelopes without compromising precision.

- High-Payload Models: Designed to carry heavier tools or components.

- Collaborative Variants (with fencing integration): Work alongside humans with safety modules and force detection systems.

What Can LR Mate Robots Do?

The LR Mate series is used in many industries due to its flexibility. Common applications include:

- Pick & Place Operations: Fast material handling and sorting.

- Assembly: The LR Mate series is used in electronics, automotive, and medical devices.

- Packaging & Palletizing: Box filling, bagging, and final packing stages.

- Machine Tending: Feeds CNC, molding, or stamping machines with minimal human labor.

- Quality Inspection: With integrated vision systems for defect detection.

- Material Removal: Including grinding, polishing, and deburring.

- Laboratory Automation: Transferring test tubes, reagents, and samples.

- Food Industry Operations: Packaging bakery items, snacks, meat, produce, etc.

- 3D Printing & Additive Manufacturing Assistance: Used as robotic arms for tool positioning.

Overall Benefit: High versatility across industrial and research environments.

Advantages of LR Mate Robots

The LR Mate family offers notable benefits:

- Compact & Flexible: The LR Mate fits into small production cells and laboratories.

- High Accuracy & Repeatability: The LR Mate is ideal for precision tasks like electronics assembly.

- Wide Range of Models: Cleanroom, food-grade, washdown, long-arm, etc.

- Low Maintenance: FANUC robots are known for long MTBF (Mean Time Between Failures).

- Supports Vision & AI Integration: The LR Mate is compatible with sensing, scanning, and inspection modules.

- Lower Operational Costs: The LR Mate consumes less energy and reduces labor expenses over time.

- Reliable Industrial Build: The LR Mate runs continuously in harsh production environments.

Disadvantages of LR Mate Robots

Despite its strengths, there are limitations:

- Limited Payload: Payload is relatively small compared to larger industrial arms, making it unsuitable for heavy-duty tasks.

- Requires Initial Investment: Upfront cost can be high for small businesses or low-volume manufacturers.

- Enclosure Needs (in some use cases): Non-collaborative models may require fencing or cages for safety compliance.

- Programming Learning Curve: Advanced programming requires technical knowledge or training.

- Specialized Integration Costs: Vision systems, grippers, and sensors add cost to deployment.

Who Uses LR Mate Robots?

They are widely deployed in:

- Automotive factories.

- Electronics assembly plants.

- Pharmaceutical companies.

- Medical labs.

- Packaging & logistics centers.

- Food processing facilities.

- Aerospace component manufacturers.

- Research institutions & universities.

The FANUC LR Mate is one of the most versatile compact industrial robots available today. Its combination of high precision, small size, energy efficiency, and flexible tooling makes it suitable for a wide range of manufacturing and laboratory applications. While it’s not suited for heavy lifting or extremely large workspaces, it excels in small-to-medium automation environments with demanding precision requirements.

You can subscribe to Science Online on YouTube from this link: Science Online

Scara robot advantages and disadvantages and What is the structure of the SCARA robot?

Serial Robots review, advantages, disadvantages and what can serial robots do?

Collaborative robot arm (cobot robots) applications, uses, advantages and disadvantages

Automation in manufacturing uses, advantages and disadvantages

Industrial robot (Auto industry) uses, advantages and disadvantages

Robot welding advantages over manual welding