FANUC CRX collaborative robot features, advantages and disadvantages

The FANUC CRX collaborative robot (often shortened to CRX cobot) is a family of lightweight, 6-axis industrial robots designed by FANUC to safely work alongside humans in shared workspaces without the need for heavy safety fencing.

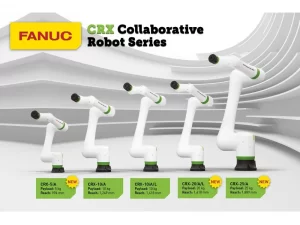

FANUC CRX collaborative robot

A FANUC CRX collaborative robot is an easy-to-use, reliable, and safe robotic arm with built-in power and force limiting technology that allows it to detect contact and stop safely, making it suitable for direct human–robot collaboration. The CRX line combines FANUC’s industrial-grade reliability with features tailored for collaboration, including simple tablet programming, hand-guiding, and versatile mounting options.

The FANUC CRX is a collaborative industrial robot series built for safe human interaction, easy programming, and flexible automation, while keeping FANUC’s trademark durability.

- Collaborative: Designed to operate around people using force sensors and safety functions.

- Flexible: Supports multiple applications like material handling, assembly, welding, inspection, polishing, and packaging.

- Accessible: Features drag-and-drop programming and manual teaching, so non-experts can set it up quickly.

- Reliable: FANUC guarantees up to 8 years of maintenance-free operation in many CRX models.

- Variants: Multiple models with different payloads (5–30 kg) and reaches (~1 m–1.7 m) to suit various industries, including food-grade and IP67 versions.

What can the FANUC CRX collaborative robot do?

The FANUC CRX collaborative robots are quite versatile. Here are various examples of what they can do, plus some of the built-in features that enable these tasks:

Material Handling:

- Moving parts between machines (machine tending).

- Pick & place tasks (e.g. from bins or conveyors).

- Palletizing or depalletizing.

Assembly Tasks:

- Using force control for insertion, pressing, or aligning parts.

- Small parts joining and assembling where precision is required.

Quality / Inspection:

- Vision-guided inspection / checking for defects. ACS can integrate vision systems (e.g. FANUC iRVision) with the CRX for this.

- Measurement tasks.

Material Removal / Finishing

- Polishing, deburring, or surface finishing. Because the CRX supports force control, it can do tasks like copying the shape or smoothing surfaces.

- Grinding / sanding type operations.

Dispensing / Coating / Sealing: Applying adhesives, sealants, coatings, glues etc. on surfaces in controlled patterns.

Food-grade / Hygienic Applications; CRX has variants for food-grade operations: white epoxy coatings, food-safe lubricants, and wash-down friendly designs. So use in food processing, packaging etc.

Welding / Arc Welding: Some models can be used with welding tasks (arc/spot welding), either in collaborative or semi-guarded setups.

Force Control / Contact Tasks:

- Inserting parts (e.g. gears, pins), polishing or deburring with built-in force control. The CRX series has a built-in force control function using the robot’s sensors.

- Surface matching, aligning, following contours.

Flexible / Mixed Use in Production: Because of its programming ease and safety, it can be integrated into production cells, shared workspaces, or paired with mobile robot bases. Also for batch or job-based manufacturing.

Features that Enable These Capabilities

- Built-in force sensing/force control without always using external force sensors. This allows delicate tasks like inserting parts, polishing etc.

- Tablet-based teach pendant + drag-and-drop programming interface. Makes programming easier, especially for operators with less robotics experience.

- Manual Guided Teaching: You can physically move the robot arm to show trajectories/gripper paths, then save them.

- Multiple models with different payloads and reaches to suit different tasks (e.g. small precise tasks vs heavy lifting or long-reach).

- Food-grade and harsh environment variants (coatings, grease, IP ratings) when needed.

- Compatible with peripherals: grippers, vision tools, end-of-arm tooling, etc.

FANUC CRX Cobot features

- Payload / Models: The CRX series has multiple models, with payloads ranging from 5 kg up to 30 kg.

- Reach: Depending on the model, reaches go roughly from ~ 994 mm (for lighter models) up to ~ 1,756 mm or more for heavier-payload, long-arm versions.

- Axes / Degrees of Freedom: 6 axes (i.e. full 6-degree motion) for all standard CRX models.

- Repeatability: High precision: values like ± 0.03 mm to ± 0.05 mm depending on the model.

- Protection / Durability: IP67 protection for the body and joints in many models, making them more robust in dusty or wet environments. Some models are “food-grade”, with special greases, coatings, etc., for hygiene and washdown.

- Safety / Collaboration: These robots have built-in force/contact detection (safe contact stop) so they can stop if they hit a person/object, allowing safe operation around humans without expensive guarding.

- Programming / Usability: Tablet teach pendant with drag-and-drop programming interface. Hand-guidance/manual guided teaching (moving the arm manually to teach positions).

- Installation / Mounting Flexibility: Can be mounted floor-level, inverted, or at an angle. The long-arm versions increase flexibility for reaching into or over large or difficult-to-access spaces.

- Power / Efficiency: Runs on standard industrial power (e.g. 100-120V or 200-240V depending on region/model) which simplifies integration. Some models are designed for energy efficiency.

- Maintenance / Reliability: FANUC claims up to 8 years of maintenance-free operation (depending on usage, environment) for the CRX line. High reliability backed by FANUC’s experience.

- Ecosystem / Accessories: There are approved devices/plugins (end-of-arm toolings, vision systems such as iRVision, sensors, etc.) that can be integrated. Also, food-grade variants, paint variants, etc.

FANUC CRX collaborative robot advantages

High reliability & low maintenance:

- FANUC claims 8 years of “zero maintenance” on components such as motors, reducers, sensors, cables, grease, castings, and PCBs.

- Durable design for industrial environments.

Safety and collaborative operation:

- CRX robots are designed to work alongside humans safely. They feature force/contact detection, safe-contact stop, power & force limiting, etc.

- Because of safety features, many applications avoid needing safety fences, reducing footprint and infrastructure cost.

Ease of programming & setup:

- They have a “Tablet Teach Pendant” with drag-and-drop programming; also, hand-guidance (lead-through teaching) for teaching paths.

- Quick deployment: smaller size, lighter controller (R-30iB mini plus) helps avoid heavy rigging.

Flexibility & versatility:

- Multiple models with varying payloads (5-30 kg and more in some FANUC cobot lines) and reach options allow matching to many tasks.

- Compatible with vision systems (2D, 3D, bin pick, area scanners), force sensors, and other accessories.

- Can be used in mobile or more dynamic setups (e.g. cobot on an AMR platform).

Proven industrial pedigree: FANUC is a well-established brand with experience in robotics and automation. That can mean better support, spare parts, and a proven supply chain.

Disadvantages of CRX Robots

Higher upfront cost & integration costs:

- The purchase price of a CRX plus the cost of parts, accessories, tooling, and safety components (if needed) can be substantial. Integration and training add to the cost.

- For smaller operations or low‐volume/low-budget, payback might be longer.

Learning curve & technical requirements:

- Despite drag-and-drop and hand guidance, programming and setting up production-grade tasks (vision, precision, complex motion) still demand technical knowledge.

- For companies without robotics specialists, extra training or hiring may be required.

Safety / Speed trade-offs:

- Because it must be safe for human interaction, speeds are limited in collaborative mode. To get fast cycles, one may need to operate in non-collaborative modes, which may require guarding or other safety measures.

- Some tasks that involve sharp tools or high forces may force you to add safety hardware or restrict the robot’s capabilities.

Payload / reach limits:

For very heavy loads or very large work envelopes, a CRX may not be enough — either another robot or a non-collaborative robot may be better. Even though CRX includes higher payload/long reach models, they still have limits.

Dependency on the FANUC ecosystem / proprietary constraints:

- Using FANUC tools, software, controllers etc. brings advantages, but also means less flexibility for using non-standard or third-party tools. Customization might be more costly.

- Spare parts, sensors, and vision systems often need to be compatible with the FANUC control/architecture.

Not always ideal for ultra-high precision or ultra-fast tasks:

For some very tight tolerances or high speed (e.g. micro-electronics assembly, semiconductor equipment), the limits of repeatability, path accuracy, vibrations, etc., may be a factor. Standard industrial precision robots might outperform in those niches.

You can subscribe to Science Online on YouTube from this link: Science Online

Scara robot advantages and disadvantages and What is the structure of the SCARA robot?

Serial Robots review, advantages, disadvantages and what can serial robots do?

Collaborative robot arm (cobot robots) applications, uses, advantages and disadvantages

Automation in manufacturing uses, advantages and disadvantages

Industrial robot (Auto industry) uses, advantages and disadvantages

Robot welding advantages over manual welding